Optimizing Manufacturing Processes for Efficiency and Quality

Introduction

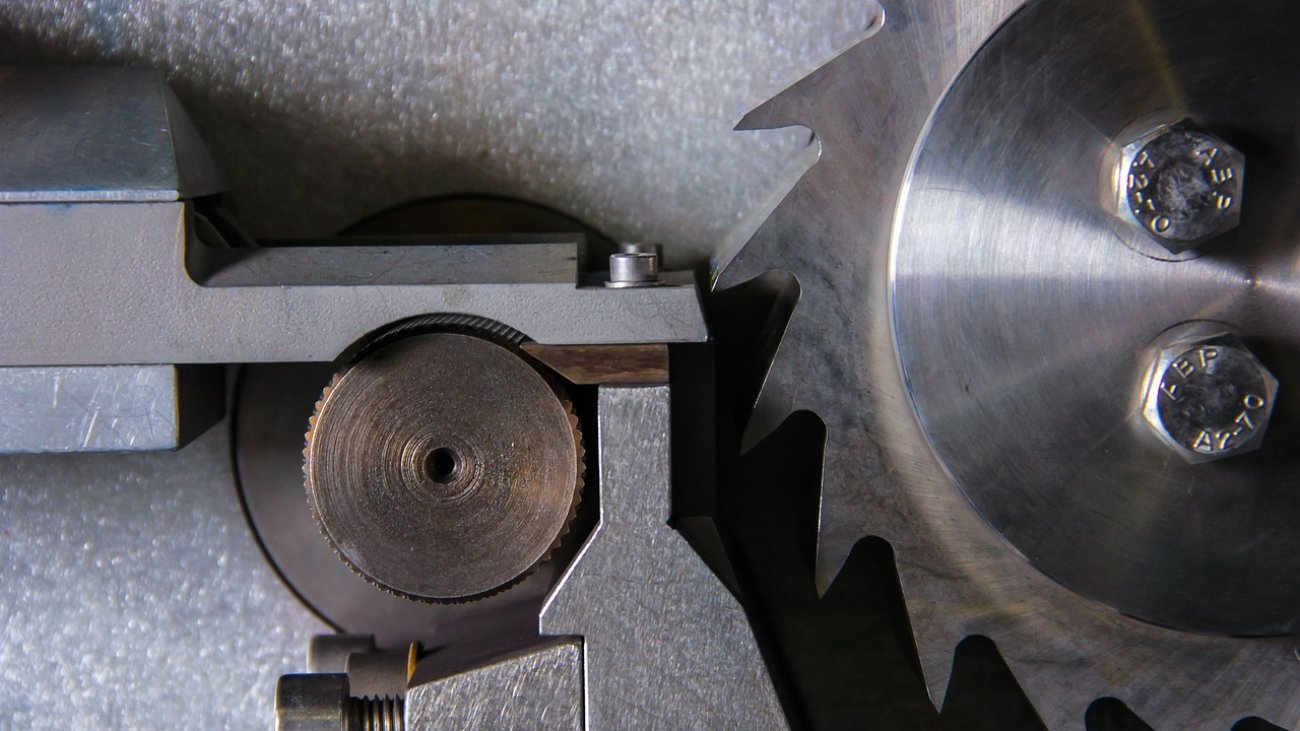

Manufacturing units are at the heart of the production industry. This blog delves into the critical aspect of optimizing manufacturing processes to enhance efficiency and maintain quality standards.

The Importance of Process Optimization

- The Role of Manufacturing Processes: An overview of manufacturing processes and their significance.

- Process Optimization and Efficiency: How optimized processes contribute to enhanced efficiency in manufacturing.

Quality Control in Manufacturing

- Quality Assurance in Manufacturing: The importance of quality control in the production of goods.

- Quality Control Methods: Common methods and practices for maintaining quality in manufacturing units.

Lean Manufacturing

- Lean Principles: An introduction to lean manufacturing principles and their role in process optimization.

- Implementing Lean: Strategies for implementing lean practices in manufacturing units.

Technological Advancements in Manufacturing

- Industry 4.0 and Smart Manufacturing: How Industry 4.0 technologies are revolutionizing the manufacturing industry.

- Quality Assurance Software: The role of software solutions in maintaining quality standards.

Efficiency and Sustainability

- Sustainable Manufacturing: The connection between process optimization and sustainability in manufacturing.

- Energy Efficiency: Strategies for improving energy efficiency in manufacturing processes.

Case Studies in Process Optimization

- Success Stories: Real-life case studies of manufacturing units that achieved significant improvements through process optimization.

- Quality Control Excellence: Examples of manufacturing units that excelled in maintaining high-quality standards.

Frequently Asked Question

1. Why is process optimization crucial in manufacturing?

● Process optimization is essential as it leads to reduced waste, increased efficiency, and cost savings.

2. What is lean manufacturing, and how does it benefit production units?

● Lean manufacturing is a systematic method for waste minimization. It benefits production units by improving efficiency and reducing costs.

3. How do manufacturing units ensure quality control in large-scale production?

● Quality control in large-scale production is achieved through standardized processes, rigorous inspections, and quality assurance techniques.